Industrial filtration is an indispensable process in various industries, ranging from food and beverage production to chemicals, pharmaceuticals, and wastewater treatment. At the heart of many filtration systems is the industrial basket filter, a robust and highly effective solution for removing solid particles from liquids. This article provides a detailed overview of industrial basket filters, their applications, benefits, and how they contribute to operational efficiency.

What is an Industrial Basket Filter?

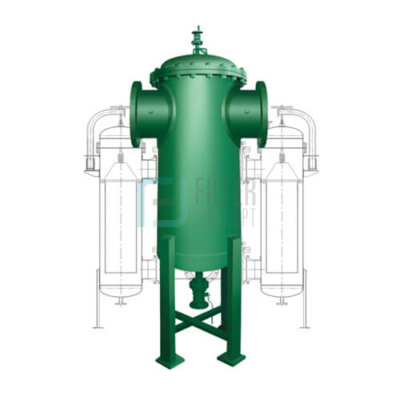

An industrial basket filter is a type of strainer used to remove contaminants such as debris, solids, or particulate matter from liquids or gases in industrial settings. Designed to handle large volumes of fluids, these filters feature a cylindrical mesh basket that holds the filtration media, typically made of stainless steel or other durable materials. The liquid passes through the filter basket, leaving contaminants behind, which are retained within the mesh.

Basket filters come in various designs and configurations, making them suitable for a wide range of applications, including water treatment, chemical processing, oil filtration, and food processing. Their primary function is to ensure the purity and quality of the liquid or gas being processed.

Key Features of Industrial Basket Filters

1. High Filtration Efficiency

One of the primary reasons for the widespread use of industrial basket filters is their exceptional filtration efficiency. The mesh used in the basket filters can be customized to meet the specific filtration requirements of various industries. The filters are capable of handling large quantities of fluid while effectively capturing even the finest particles. This high efficiency ensures that the downstream systems, such as pumps and pipes, are protected from damage caused by contaminants.

2. Versatile Design Options

Basket filters come in different sizes, materials, and configurations to suit a wide range of applications. They can be installed in both horizontal and vertical orientations depending on the available space and the specific needs of the filtration system. Whether it’s for a high-flow system or a low-flow application, there is a basket filter designed to meet every requirement.

3. Ease of Maintenance

Another notable advantage of industrial basket filters is their ease of maintenance. Most basket filters are designed with removable baskets, allowing for simple cleaning or replacement of the filter media. This makes it easy to keep the filtration system running smoothly, reducing downtime and improving overall productivity. Additionally, the basket filter’s self-cleaning mechanism can automatically expel debris, minimizing the need for manual intervention.

4. Durability and Longevity

Basket filters are designed to withstand high pressures and harsh environments, making them incredibly durable. Whether used in a chemical plant, wastewater treatment facility, or oil refinery, these filters are built to last and provide long-term performance. The materials used, such as stainless steel, are resistant to corrosion and wear, ensuring the filters remain effective over time.

Applications of Industrial Basket Filters

1. Water Treatment

In the water treatment industry, industrial basket filters are used to remove large solids and debris from raw water before it undergoes more advanced filtration processes. These filters play a vital role in protecting water treatment equipment such as pumps, valves, and membranes from clogging or damage. By removing large particles, basket filters ensure the efficiency and longevity of downstream equipment.

2. Food and Beverage Industry

In the food and beverage sector, industrial basket filters are essential for ensuring the cleanliness and safety of liquids used in production. They are commonly used in filtering oils, juices, and syrups, removing unwanted particles that could affect the quality of the final product. Basket filters help maintain product consistency and reduce the risk of contamination during processing.

3. Chemical and Pharmaceutical Industries

Chemical and pharmaceutical companies rely on industrial basket filters to maintain the purity of chemicals and solvents. Basket filters help remove particulate matter, ensuring that the final product meets stringent quality standards. The use of these filters also extends to solvent recovery processes, where the filter helps remove contaminants that could compromise the purity of the recovered solvent.

4. Oil and Gas Industry

In the oil and gas industry, basket filters are crucial for protecting sensitive equipment from abrasive materials, water, and other contaminants found in crude oil or natural gas. They help maintain the efficiency of refining processes and prevent the clogging of pipelines, which could lead to costly downtime.

5. Wastewater Treatment

Industrial basket filters are commonly used in wastewater treatment plants to remove suspended solids and other contaminants before water is treated further or released into the environment. These filters contribute to environmental protection by ensuring that treated water meets regulatory standards for discharge.

Types of Industrial Basket Filters

1. Single Basket Filter

The single basket filter is the most straightforward design, featuring a single filter basket. It is ideal for systems that do not require complex filtration and can accommodate smaller flow rates. This type of filter is often used in low-flow applications and can be easily maintained.

2. Duplex Basket Filter

The duplex basket filter design features two baskets, allowing for continuous filtration. When one basket becomes clogged or requires cleaning, the other basket can be put into service, ensuring that the filtration process is not interrupted. This design is particularly useful in industries where continuous filtration is critical, such as in oil refineries and chemical processing plants.

3. T-Basket Filter

The T-basket filter features a T-shaped design that allows for a more compact installation in tight spaces. This type of filter is commonly used in applications where space is limited but the need for efficient filtration remains high. T-basket filters are often found in water treatment and food processing industries.

Benefits of Using Industrial Basket Filters

1. Improved Equipment Longevity

By removing solid contaminants, industrial basket filters help extend the life of pumps, valves, and other critical components within the filtration system. This can result in significant cost savings over time, as the frequency of repairs and replacements is reduced.

2. Reduced Downtime

Since industrial basket filters are easy to maintain, they help minimize downtime in industrial operations. With the ability to clean or replace the filter baskets quickly, companies can maintain smooth, continuous operation without costly delays.

3. Increased Process Efficiency

By ensuring that liquids are free from large debris and particulate matter, basket filters contribute to the overall efficiency of industrial processes. Clean liquids ensure that other equipment, such as heat exchangers, pumps, and pipes, work at optimal performance, reducing the risk of clogging or damage.

4. Cost-Effective Solution

When compared to other filtration methods, such as cartridge filters or bag filters, industrial basket filters are a cost-effective solution for many industries. They provide a high level of filtration at a lower cost, making them an attractive option for businesses looking to optimize their operations without compromising on quality.

Conclusion

Industrial basket filters are essential components of many filtration systems across a wide range of industries. Their ability to efficiently remove contaminants from liquids and gases makes them a critical part of maintaining clean systems and protecting valuable equipment. With their durability, versatility, and ease of maintenance, industrial basket filters help improve process efficiency, reduce downtime, and ensure long-term operational success. Whether you are in water treatment, food processing, chemical manufacturing, or oil refining, these filters are a cost-effective and reliable solution to meet your filtration needs. read more…